1. Introduction to Modbus RTU

Modbus RTU is a widely recognized and utilized communication protocol in the field of industrial automation. Developed by Modicon (now Schneider Electric) in 1979, it was designed to facilitate communication between various electronic devices, primarily programmable logic controllers (PLCs). The protocol has since become a standard method for transmitting information over serial lines, establishing its importance in industries ranging from manufacturing to energy management. Modbus RTU’s simplicity, reliability, and interoperability have made it an essential component in the seamless operation of modern automated systems.

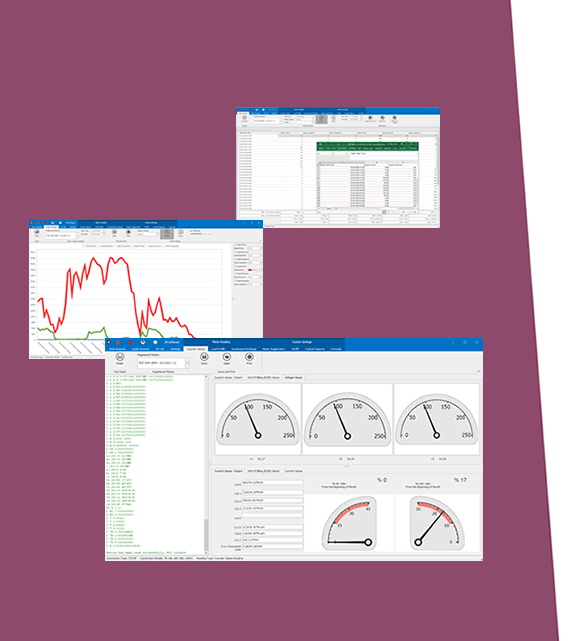

“This protocol primarily uses an RS-232 or RS-485 serial interfaces for communications and is supported by every commercial SCADA, HMI, OPC server and data acquisition software program in the marketplace. This makes it very easy to integrate Modbus-compatible equipment into new or existing monitoring and control applications.”

Reference: https://www.rtautomation.com/technologies/modbus-rtu/

2. Modbus RTU Fundamentals

Modbus RTU (Remote Terminal Unit) is a serial communication protocol designed for connecting industrial electronic devices. It operates over RS-485, RS-422, and RS-232 lines, enabling devices to communicate with each other through a master-slave architecture. The communication principles of Modbus RTU involve data packets called frames, which consist of an address field, function code, data, and an error-checking field. This frame structure ensures data integrity and reliability, making it suitable for various industrial applications where timely and accurate data exchange is critical.

Reference: https://theautomization.com/modbus-ascii-vs-modbus-rtu-vs-modbus-tcpip/

3. Modbus RTU Communication Process

The communication process in Modbus RTU follows a master-slave model, where a single master device controls multiple slave devices. Each device on the network has a unique address, enabling the master to direct commands and requests to specific devices. The master initiates communication by sending a request frame to a slave, which then processes the request and responds accordingly. Error checking, typically using Cyclic Redundancy Check (CRC), ensures the accuracy of the transmitted data. This methodical approach to communication helps in maintaining system integrity and preventing data corruption.

4. Modbus RTU Implementation

Implementing Modbus RTU requires a combination of suitable hardware and software components. On the hardware side, RS-485 or RS-232 interfaces are commonly used due to their robustness and noise immunity. The software implementation involves configuring the Modbus RTU protocol on both the master and slave devices, often using PLCs, HMIs (Human-Machine Interfaces), or other industrial controllers. A typical Modbus RTU network includes multiple devices connected in a daisy-chain configuration, with termination resistors used to prevent signal reflection. Proper implementation ensures efficient and reliable communication across the network.

5. Modbus RTU vs. Other Modbus Variants

Modbus RTU stands out among other variants like Modbus ASCII and Modbus TCP/IP due to its simplicity and efficiency. Unlike Modbus ASCII, which encodes data in ASCII characters, Modbus RTU uses a compact binary format that reduces the size of the data frames and improves communication speed. Compared to Modbus TCP/IP, which operates over Ethernet, Modbus RTU is more suited for short-distance, low-cost applications. However, each variant has its unique advantages and is chosen based on specific application requirements, such as the need for long-distance communication or integration with IP-based networks.

6. Advantages and Limitations of Modbus RTU

Modbus RTU offers several advantages, including ease of implementation, low cost, and widespread industry acceptance. Its deterministic communication ensures timely data exchange, making it ideal for real-time industrial applications. However, it also has limitations, such as limited data transfer rates and shorter communication distances compared to modern Ethernet-based protocols. Additionally, the master-slave architecture can be a bottleneck in systems requiring simultaneous multi-device communication. Addressing these challenges involves using repeaters for extended distances and adopting hybrid communication systems that combine Modbus RTU with other protocols.

7. Applications of Modbus RTU in Industry

Modbus RTU is extensively used in various industrial applications, thanks to its reliability and ease of use. In industrial automation, it connects PLCs, sensors, and actuators, facilitating seamless control and monitoring of manufacturing processes. Building management systems utilize Modbus RTU to integrate HVAC, lighting, and security systems, enhancing operational efficiency and energy management. Additionally, in the energy sector, Modbus RTU enables the monitoring and control of power generation, distribution, and consumption, contributing to optimized energy usage and reduced operational costs.

“The RTU version is an open standard, meaning that manufacturers can build it into their equipment without having to pay royalties. It is the most pervasive communications protocol in industrial automation and is now the most commonly available means of connecting industrial electronic devices.”

Reference: https://www.rtautomation.com/technologies/modbus-rtu/

8. Future of Modbus RTU

The future of Modbus RTU looks promising, with ongoing advancements in industrial communication technologies. Emerging trends such as the Industrial Internet of Things (IIoT) and Industry 4.0 are driving the integration of Modbus RTU with more advanced protocols and technologies. This integration aims to enhance interoperability, data exchange, and system efficiency. Furthermore, developments in wireless communication and cybersecurity are expected to bolster Modbus RTU's capabilities, ensuring its continued relevance and application in modern industrial environments.

9. Conclusion

Modbus RTU remains a cornerstone in the realm of industrial communication, thanks to its robustness, simplicity, and reliability. Its role in facilitating seamless data exchange across various industrial devices underscores its importance in automation and control systems. While it faces challenges from newer technologies, continuous improvements and integrations ensure that Modbus RTU will remain a viable and valuable protocol for years to come.