1. Introduction to Modbus TCP

Modbus TCP, also known as Modbus TCP/IP, is a widely adopted communication protocol in the industrial automation sector. It was developed to enable Modbus communication over Ethernet networks, combining the reliability and simplicity of the Modbus protocol with the versatility of Ethernet. This evolution from the traditional serial communication methods has allowed for faster, more efficient data transmission, making it a critical component in modern industrial systems.

2. Modbus TCP Fundamentals

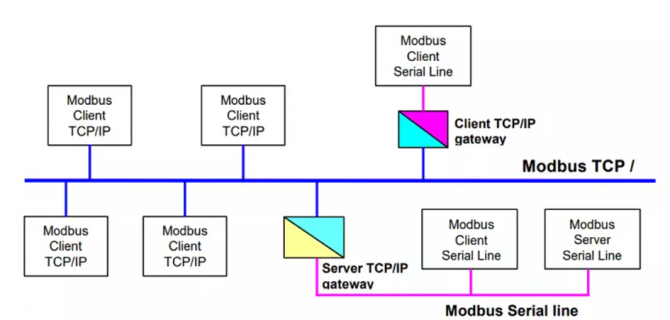

Modbus TCP operates over TCP/IP networks, leveraging the standard Ethernet infrastructure to connect devices. Unlike Modbus RTU, which uses serial communication, Modbus TCP encapsulates Modbus frames within TCP/IP packets. This enables communication over larger distances and through complex network topologies. The fundamental structure of Modbus TCP includes an IP header, a TCP header, and the Modbus Application Data Unit (ADU), which comprises the function code and data fields. This layered approach ensures robust and flexible communication.

Scheme Reference: https://www.modbus.org/docs/Modbus_Messaging_Implementation_Guide_V1_0b.pdf

3. Modbus TCP Communication Process

The communication process in Modbus TCP follows a client-server model. In this model, a client device initiates communication by sending a request to a server device, which then processes the request and responds accordingly. Each device is identified by an IP address, and the communication follows the standard TCP/IP protocol suite. The error checking in Modbus TCP is managed by the underlying TCP/IP layers, providing reliable data transmission without the need for additional error-checking mechanisms within the Modbus protocol itself.

4. Modbus TCP Implementation

Implementing Modbus TCP requires appropriate hardware, such as Ethernet-compatible devices, and software capable of handling TCP/IP communication. The network setup typically involves Ethernet switches, routers, and cables to connect devices in a star topology. Software implementation involves configuring IP addresses, subnet masks, and other network parameters to ensure seamless communication. Modbus TCP can be integrated into existing Ethernet networks, allowing for easy expansion and integration with other networked systems.

5. Modbus TCP vs. Other Modbus Variants

Modbus TCP offers several advantages over other Modbus variants like Modbus RTU and Modbus ASCII. While Modbus RTU and ASCII are limited by the constraints of serial communication, Modbus TCP leverages the speed and flexibility of Ethernet networks. This results in higher data transfer rates and the ability to connect devices over long distances. Additionally, Modbus TCP supports concurrent communication with multiple devices, unlike the master-slave limitation of Modbus RTU. However, each variant has its specific use cases, with Modbus RTU being preferred in simpler, cost-sensitive applications.

6. Advantages and Limitations of Modbus TCP

The primary advantages of Modbus TCP include high-speed communication, easy integration with existing Ethernet networks, and support for a large number of devices. Its use of standard TCP/IP protocols ensures compatibility with a wide range of networking equipment and software. However, Modbus TCP also has limitations, such as increased complexity in network setup and higher costs associated with Ethernet hardware. Additionally, the reliance on Ethernet infrastructure can introduce vulnerabilities to network security, necessitating robust cybersecurity measures.

7. Applications of Modbus TCP in Industry

Modbus TCP is extensively used in various industrial applications due to its efficiency and flexibility. In industrial automation, it connects PLCs, HMIs, and other control devices over Ethernet, facilitating real-time monitoring and control. Building management systems utilize Modbus TCP to integrate HVAC, lighting, and security systems into a unified network. The energy sector also benefits from Modbus TCP, using it for monitoring and controlling power generation, distribution, and consumption. Its ability to handle large-scale, complex networks makes it ideal for these applications.

“The most common use of the protocols at this time is for Ethernet attachment of PLCs, I/O modules and gateways to other simple field buses or I/O networks.”

Reference: https://www.rtautomation.com/technologies/modbus-tcpip/

8. Future of Modbus TCP

“Since the release of Modbus TCP/IP, most of its advancements have not been in the protocol itself, but in the surrounding Ethernet technologies.”

Reference: https://www.automationworld.com/communication/article/33015041/modbus-tcp-ip-keeps-it-simple

The future of Modbus TCP is closely tied to the advancements in Ethernet technology and the growing adoption of Industrial Internet of Things (IIoT) and Industry 4.0. These trends emphasize the need for high-speed, reliable communication protocols like Modbus TCP. The integration of Modbus TCP with wireless technologies and cloud computing is expected to enhance its capabilities further. Additionally, ongoing improvements in network security will address the vulnerabilities associated with Ethernet-based communication, ensuring Modbus TCP remains a critical protocol in industrial automation.

9. Conclusion

Modbus TCP has revolutionized industrial communication by combining the robustness of the Modbus protocol with the versatility of Ethernet. Its role in enabling efficient and reliable data exchange across various industrial applications underscores its importance. Despite facing challenges related to network complexity and security, Modbus TCP's continued evolution and integration with emerging technologies ensure its relevance and utility in modern industrial systems.