1.Introduction

The STG series provides a cutting-edge solution for converting Wireless M-Bus (WMBus) OMS (Open Metering System) data to Modbus protocols, enabling seamless integration between advanced metering systems and industrial automation platforms. By focusing on Modbus TCP and RTU compatibility, the STG series ensures interoperability and ease of deployment in diverse operational environments.

2.Why Convert WMBus OMS Data to Modbus?

Wireless M-Bus is the preferred communication protocol for smart meters, transmitting real-time utility consumption data wirelessly. However, industrial control systems like SCADA and PLCs primarily rely on Modbus for data exchange. The STG series bridges this gap, ensuring metering data can be integrated into industrial systems for centralized monitoring and control.

3.Exclusive Features for Modbus Conversion

Unlike general-purpose data parsers, the STG series is tailored specifically for converting Wireless M-Bus OMS data to Modbus protocols. Key features include:

• WMBus OMS to Modbus TCP Converter: Facilitates integration with Ethernet-based networks by converting WMBus data into Modbus TCP format.

• WMBus OMS to Modbus RTU Converter: Enables communication with legacy devices via serial interfaces using Modbus RTU.

• Flexible Transparent Mode: Sends raw WMBus packets to/from TCP/IP or serial interfaces for custom applications.

• OMS Compliance: Full support for OMS encryption and standardization ensures compatibility and data security.

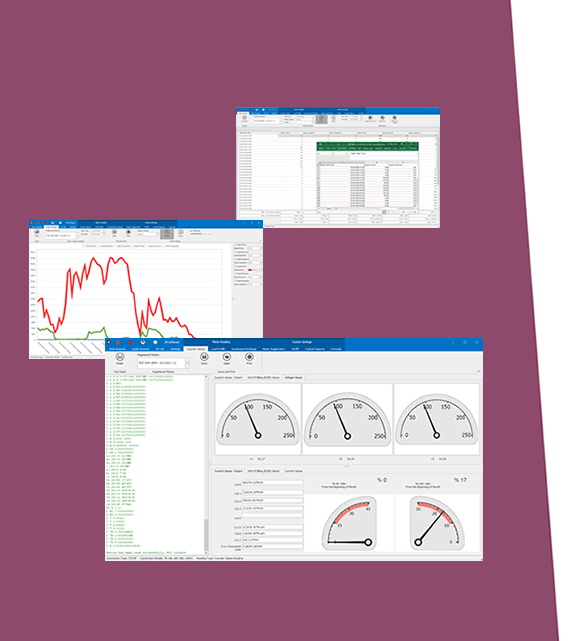

• Advanced Diagnostics: Built-in tools for monitoring communication and debugging issues during system setup.

4.Step-by-Step Guide to Using the STG Series for Modbus Conversion

1. Configuration:

o Connect the STG device to your computer via TCP/IP interface.

o Use the bultin web interface to configure the desired Modbus mode (TCP/RTU).

o Enter OMS encryption keys and set the communication frequency for the WMBus network.

2. Data Reception:

o Position the STG device within range of the Wireless M-Bus meters.

o Start data reception using the software. The STG device will decode OMS packets and prepare them for Modbus transmission.

3. Modbus Integration:

o For Modbus TCP: Connect the STG device to an Ethernet network and configure the Modbus master to communicate with the STG’s IP address.

o For Modbus RTU: Connect the STG device to a serial port and ensure the Modbus master is set to the correct baud rate and communication parameters.

o Map the WMBus data to Modbus registers as needed for your application.

5.Unique Applications of the STG Series for Modbus Conversion

• Industrial Energy Monitoring: Monitor utility consumption in factories and warehouses, integrating data into SCADA systems for efficiency optimization.

• Building Automation: Centralize water, gas, and electricity meter readings into a single building management system using Modbus.

• Utility Meter Integration: Enable utility providers to incorporate Wireless M-Bus OMS data into existing Modbus-based infrastructure.

• Smart City Projects: Connect smart metering data to city-wide control and analytics platforms for resource optimization.

6.Advantages of the STG Series in Modbus Applications

• Streamlined Integration: Eliminates the need for complex middleware, enabling direct communication between WMBus and Modbus systems.

• Cost Efficiency: Reduces expenses by leveraging standard protocols and avoiding proprietary solutions.

• High Reliability: Ensures accurate and secure data transmission with OMS compliance.

• Customizability: Adapts to various project needs through flexible configuration options.

7.Conclusion

The STG series redefines the process of integrating Wireless M-Bus OMS data into Modbus-based systems. By offering robust conversion capabilities, it empowers utilities, industrial operators, and smart city developers to enhance their operations with real-time, reliable metering data. Whether addressing legacy systems or modern IoT networks, the STG series ensures a seamless, secure, and efficient solution for Modbus integration.